R & D and production

PRODUCT LIST

RECENT NEWS

HOT KEYWORDS

CONTACT

- contact way

- ADDRESS

- Address: No.19, Filter Material Industrial Park, Fucheng, Funing, Jiangsu

Email:jszzjt@126.com

qq:604258913

World's Official Website:www.qdweijie.com - TELEPHONE

- 18361175589

- Monday to Saturday 8:00-17:30

Telephone:0515-87266087

Fax:0515-87354486

Production process management

Current of page:Home > R & D and production > Production process managementRaw material:All raw materials are made of high quality chemical fiber and inorganic fiber. High strength filament polyester fabric, 80 off alkali glass fiber base fabric and high performance fabric are imported.

Acupuncture procedure:The advanced double tin needling equipment is adopted, and the high density and high density needling is carried out with scientific seasoning. Ensure that the fabric surface smooth, smooth, density and other performance indicators.

After treatment process:Singeing, calendering, heat setting, waterproof and oil proof, PTFE coating and PTFE coating processing.

Sewing process: The filter cloth is cut by cutting machine and sewed by manual and automatic suture. According to customer sewing requirements, do three line sewing and high temperature hot melt adhesive.

Quality inspection procedure: The products under the machine, the quality of products by the inspector detection, measurement, quantitative plate length and diameter and suture requirements. Ensure that customers use reliable, high-quality filter bags.

Packaging process:According to customer packing requirements, we will use cardboard boxes or woven bags, carefully packaged delivery bags.

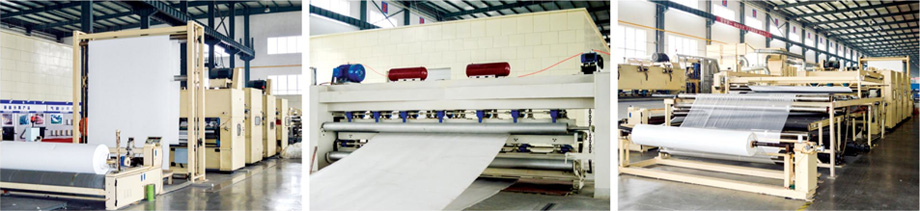

MANUFACTURING EQUIPMENT+PRODUCTION CAPACITY

Annual output of 1000 square meters of high temperature glass fiber filter cloth (bag), 1000 tonnes of non-alkali short cut wire, high temperature and sewing thread, 800 tons of bulk yarn, 600 tons of processing yarn, group has already set, singeing, hot-rolled, impregnation, drying, coating, cutting, sewing and other advanced equipment.

Width of 1.8 meters, 1.8 meters non-woven production line 6, with an annual output of 10 million square meters of non-woven filter material; And Shanghai LingQiao cooperation of two coated production lines, producing compound ptfe microporous membrane filter material 600 square meters; At the same time have a width of 3 meters, 4 meters waterproof coiled material production line two, a wide geotextile production lines, with an annual output of 1000 square meters of all kinds of waterproofing materials.